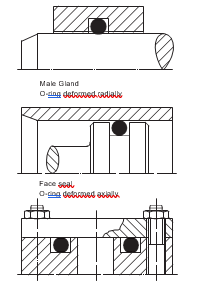

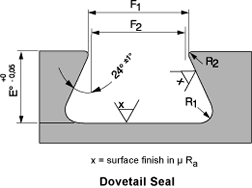

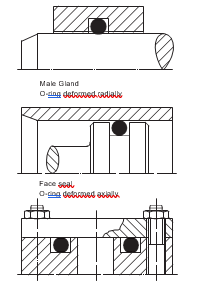

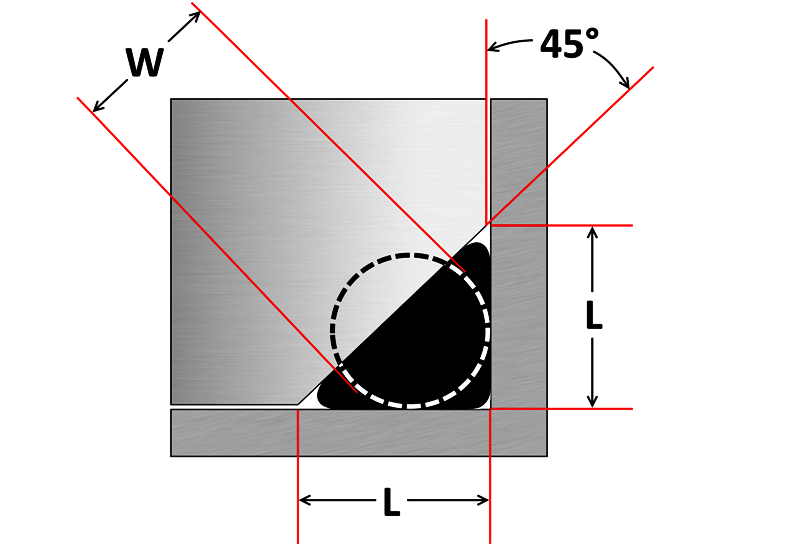

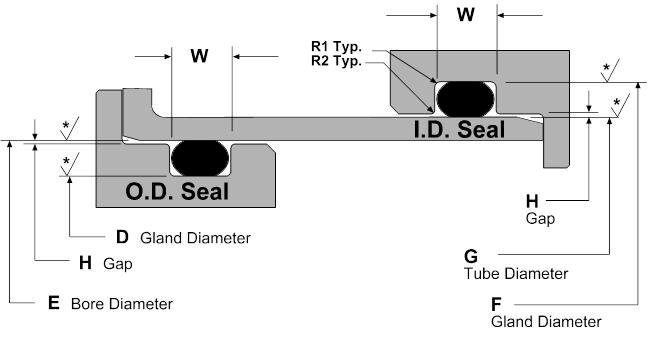

Dovetail ORing Gland Design In a dovetail oring gland application the oring squeeze is primarily axial in direction, where a valve exerts force on the top and bottom of the orings surfaces Typically used in static or slow moving applications the dovetail orings gland purpose is to properly hold the oring in place during machine operationThere are two types of radial designs 1 Male or Plug the Oring groove is located on a plug which is inserted into the housing or cylinder (fig 123) 2 Female or Tube the Oring groove is located in the housing or cylinder and a tube is installed through the Oring lD (fig 124) Male or Plug Seal design is based onThe squeeze or rate of compression is a major consideration in Oring seal design and differs per Oring application design Orings with smaller cross sections are squeezed by a higher percentage to overcome the relatively higher groove dimension tolerances In static applications the recommended squeeze is usually between 1530%

Untitled Document

Seal groove design for o ring

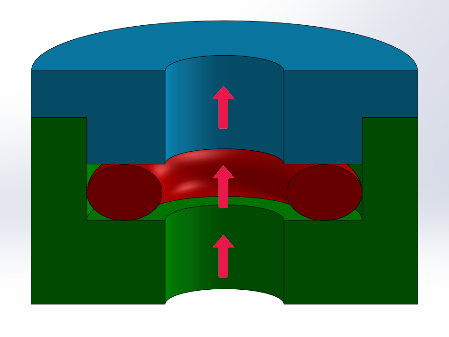

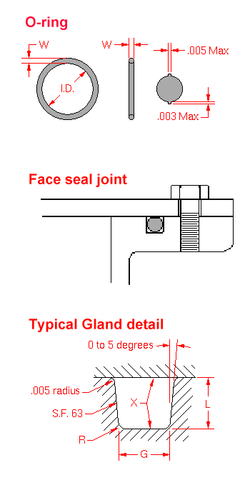

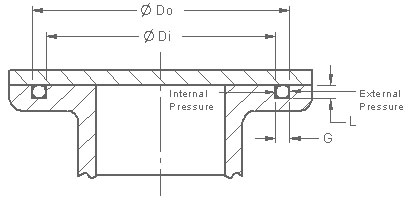

Seal groove design for o ring-Pressure side of the groove The use of two Orings on the chamber's sealing surface has proven successful in holding the required pressure applied on the 15 foot diameter seal as illustrated in Figure 2 The reason for the two Oring design is that it is possible to pump out the space between the two OringsIt is a elastomer with a round crosssection designed to be seated in a groove and compressed during assembly between two or more parts, creating a seal at the interface

2 Design And Detail Information O Rings Stock O Ring Webshop

ORing Design Considerations What to Know About ORing Squeeze, Stretch, Compression, and More Our oring groove design guides list default oring groove dimensions for the most basic applications and are intended to be used with the following oring groove design considerations to engineer on oring gland to optimize specific application performanceOring seal The tables at the right and the diagram below provide the recommended gland design parameters In addition, the gland surfaces must be free from all machining irregularities, and the gland edges should be smooth and true and free of nicks, scratches, and burrs A perfectly designed Oring seal is of little use if the OringWelcome to our Oring Groove Design section Here you will find an Oring groove design guide to help you with your Oring gland dimensions Through our extensive research we believe that these Oring groove dimensions and fit details will provide the optimum Oring compression squeeze for your seal to prevent Oring leaks

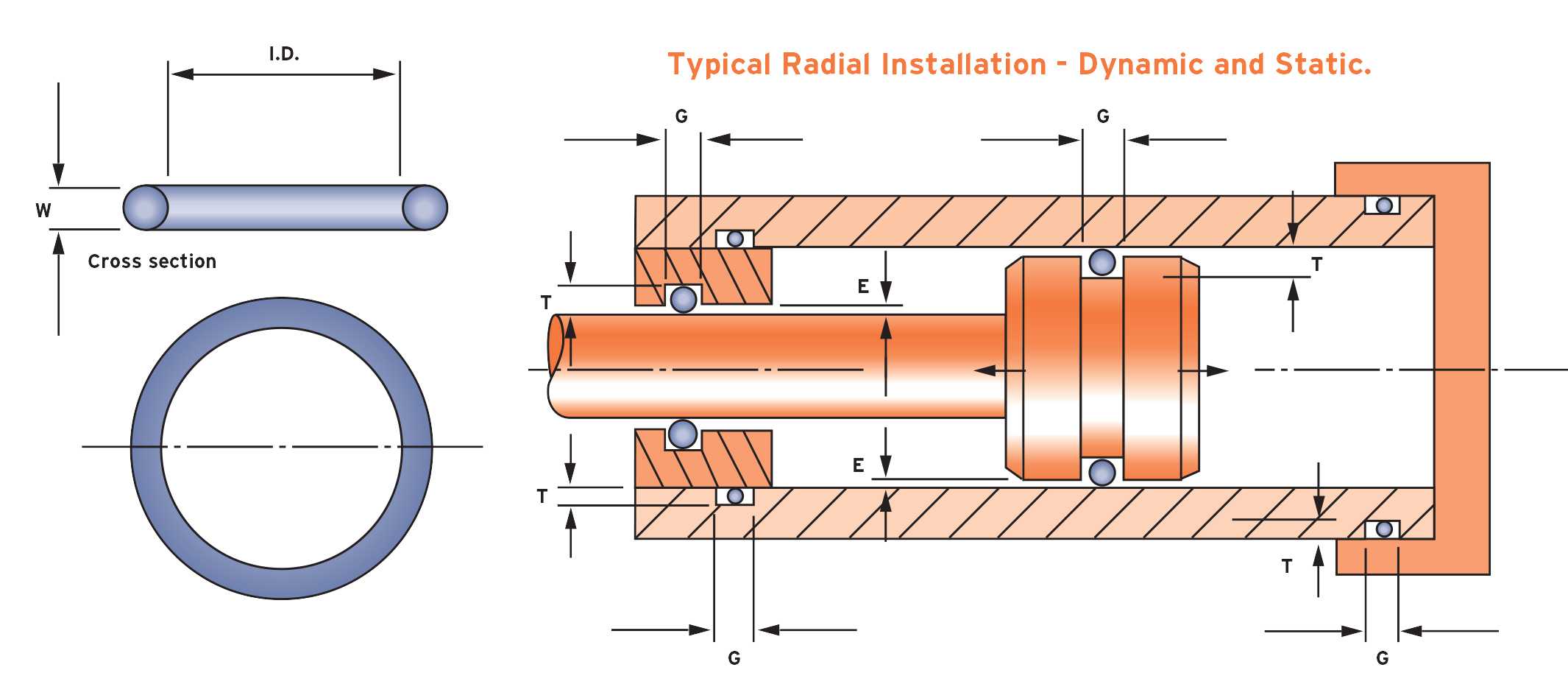

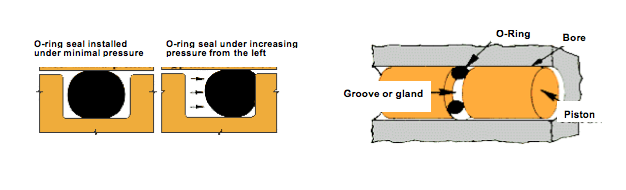

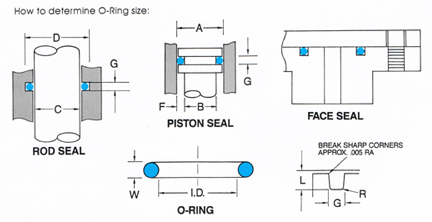

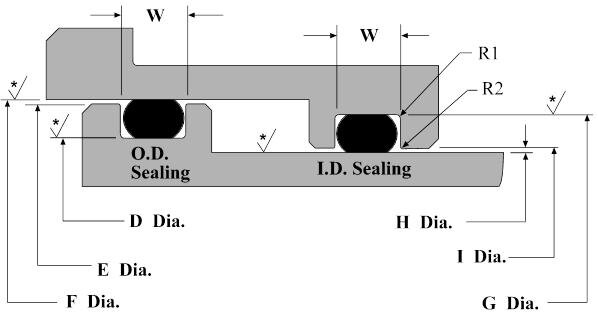

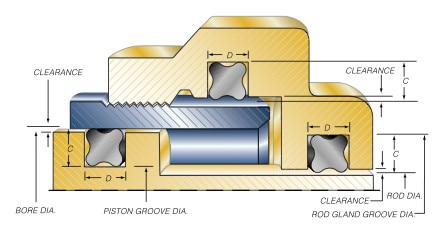

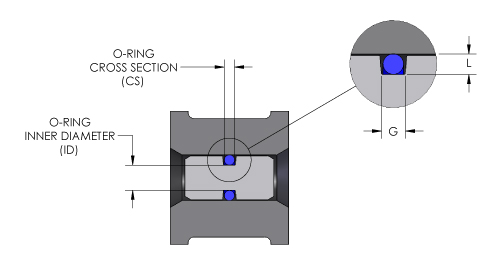

Static Radial ORing Gland Design In a static radial seal application the oring is squeezed between the inner ID and the outer OD surfaces of the oring, with no relative motion between parts of the gland that come in contact with the oring The table below lists recommended dimensions for static radial seal glands by AS568A oring dashDesigning the parts of an application where orings will be applied is termed "oring groove design" In order to seal properly, the oring has to deform in the application by being compressed and stretched in any number of waysTotal indicator reading between groove and adjacent bearing surface All surfaces and corners must be free of tool marks and scratches ORing groove and dimensions may be calculated as follows (please refer to chart above) Given Example

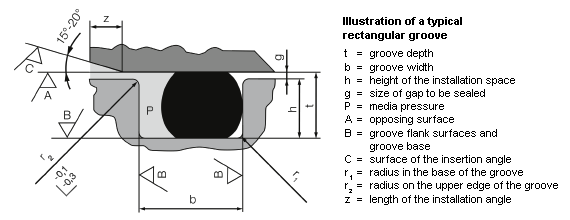

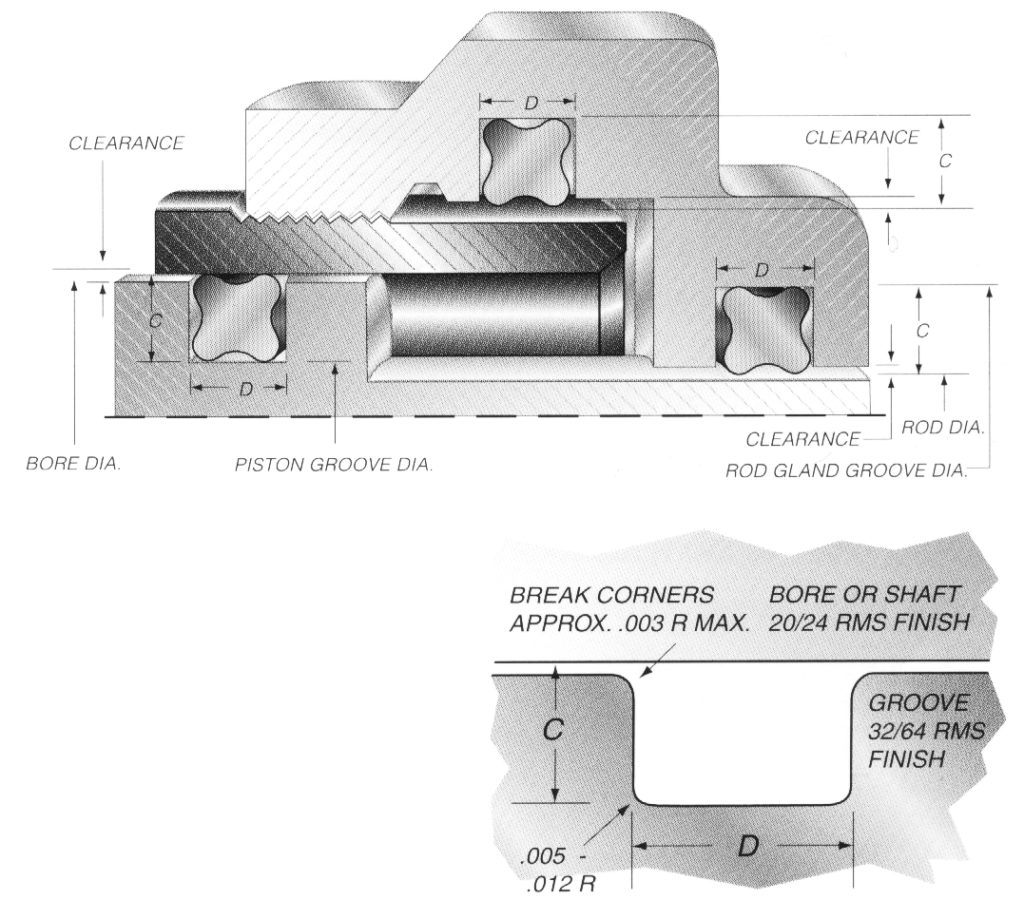

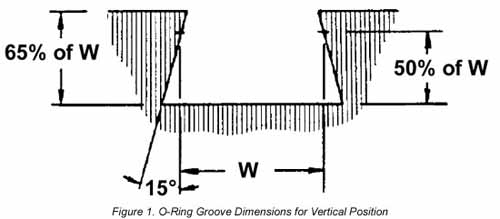

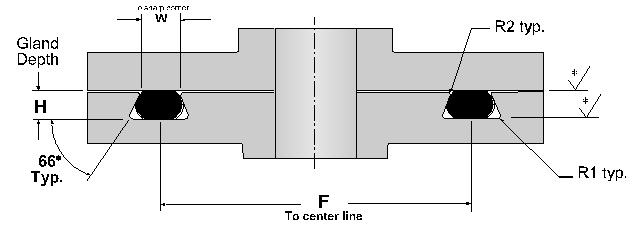

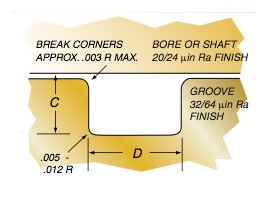

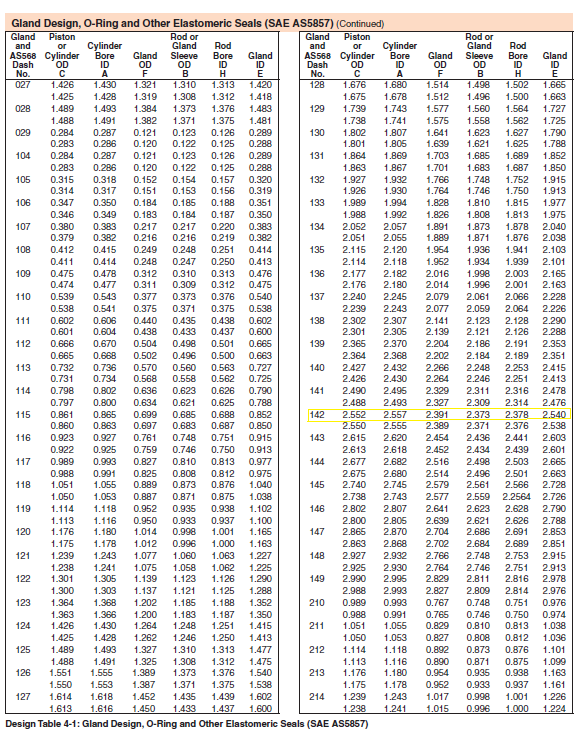

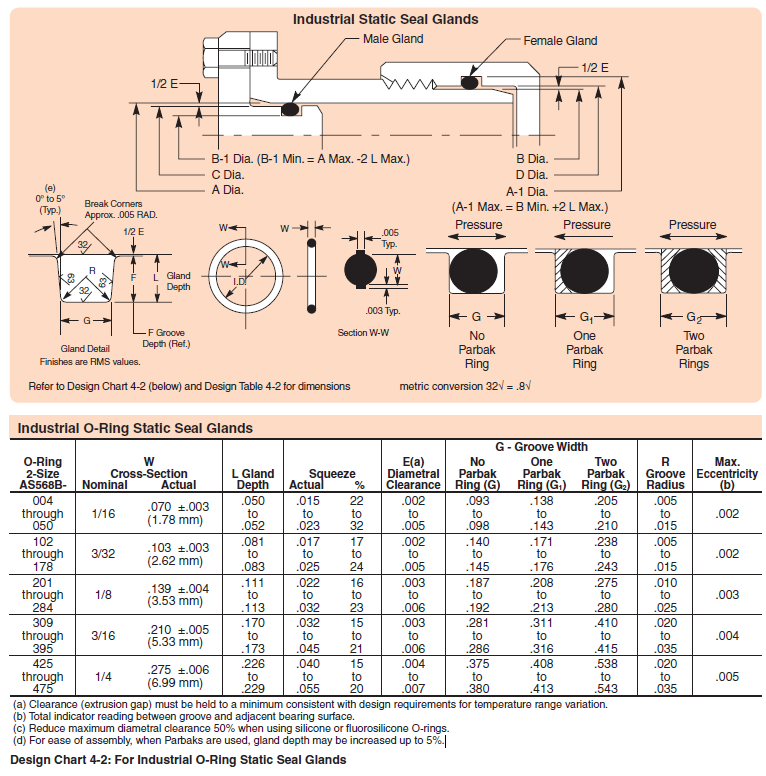

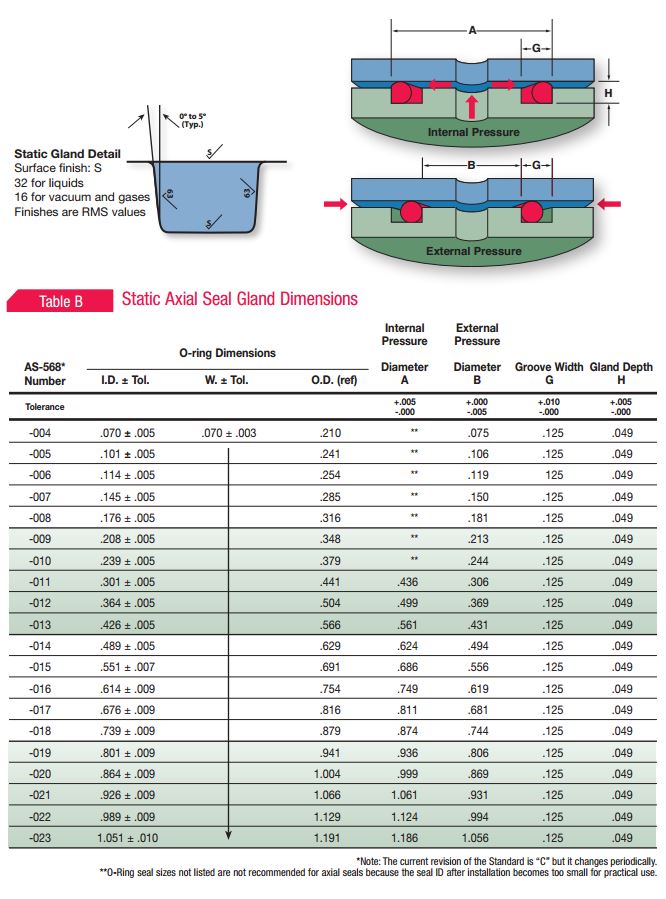

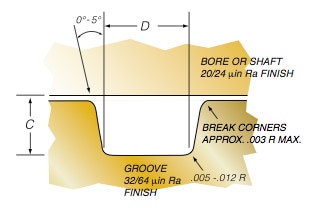

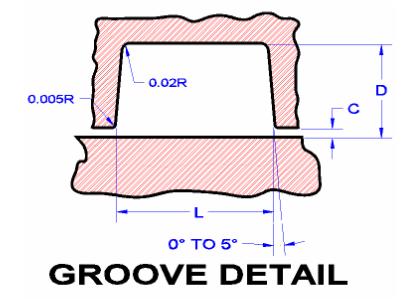

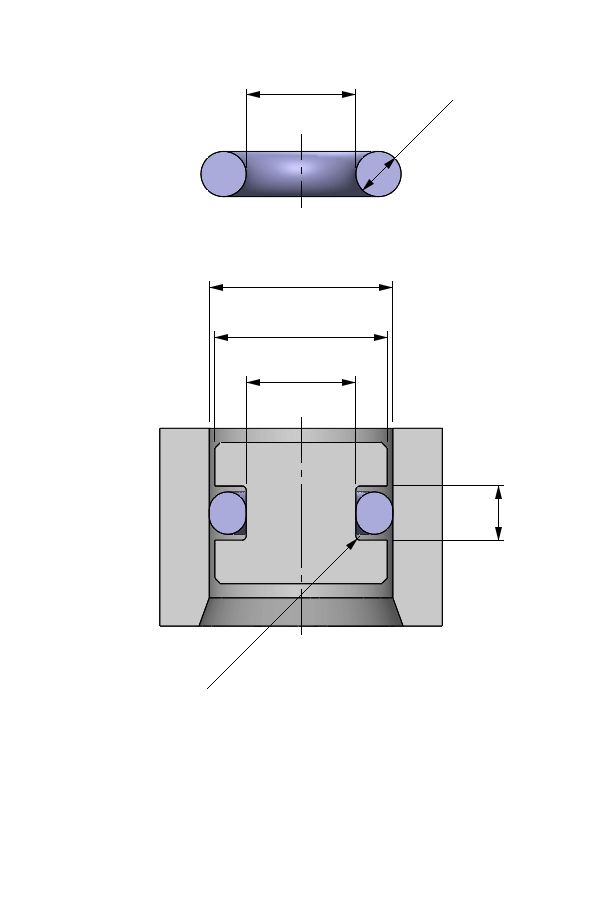

Rings Ring Rings Radius Max ORing Gland Design For Static Seals Note Table A contains general sealing guidelines More specific information is available throughout this guide †Note It is recommended that an Oring with tighter CS tolerance (±002) be requested One general guideline for good Oring application and design is toGroove Design ORing Seals for Static and NonRotary Dynamic Applications Crosssection Select an ORing crosssection size from the available standard sizes If you are unsure what crosssection size to use, see here Clearance Determine the maximum clearance present in10 ORING SEALS – THEORY AND DESIGN PRACTICES Theory An oring seal consists of an oring and a properly designed gland which applies a predictable deformation to the oring The gland is basically a groove dimensioned to a certain height "H" and width "W" (Figure 1) to allow a fixed compression of the oring

American Seal Packing General Design And Gland Dimensions

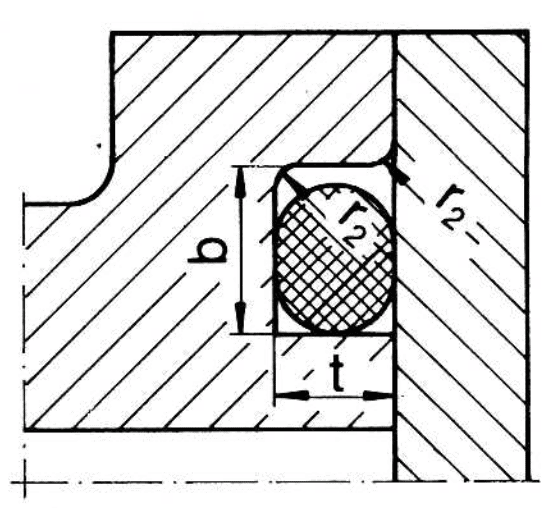

O Ring Groove Depth T O Ring Groove Width B Radial An Axial O Ring Fitting

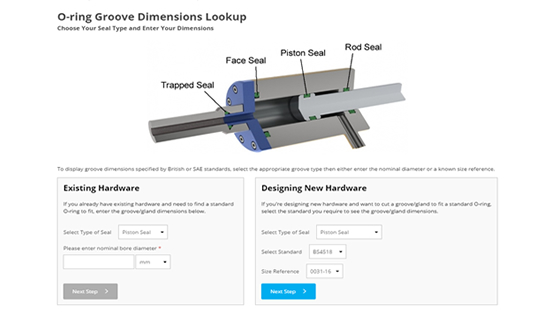

AS568 Oring & gland design utility Oring Piston Seal FastDashTM Oring Piston Seal Design Guide Enter the "A" diameter (ie bore diameter), Press the "Submit" button, The appropriate dash no orings will be listed along with their associated groove detailsBetween 15%25% squeeze on the ORing Static seals can tolerate higher volume swell of the O Ring than dynamic seals B Dynamic seal grooves are normally designed to have about 15% squeeze on the ORing Less squeeze increases probability of leakage while more squeeze increases friction and probability of spiral failureGroove design guide for static oring face seals provides default recommendations on width, depth, diameter and more for basic applications Oring face seals are used in a variety of applications, including bolted flanges or removable lids Simple selection tool to

Design Of Oring Seals Design Of Oring Seals

O Rings Designing

Now, follow the steps below to design your own oring seal and oring groove Step 1 Choose your rubber properties by going to our Oring Material Guide section Step 2 Make sure that the material you choose will withstand the temperature of your system by going to this rubber temperature range chart Step 3General Engineering Menu ORings Suppliers Molded ORings Services ORings Design Guidelines, Specifications, Materials An Oring , also known as a packing , is a flexible gasket in the shape of a loop; A common mistake is to design the groove width to "pinch" the oring crosssection, so it is held in the groove The critical design point to keep in mind is homogenous rubber acts like a highly viscous fluid Therefore, the volume is displaced, not compressed A good seal design will provide more gland void than seal volume

O Ring Groove Design Daemar Inc

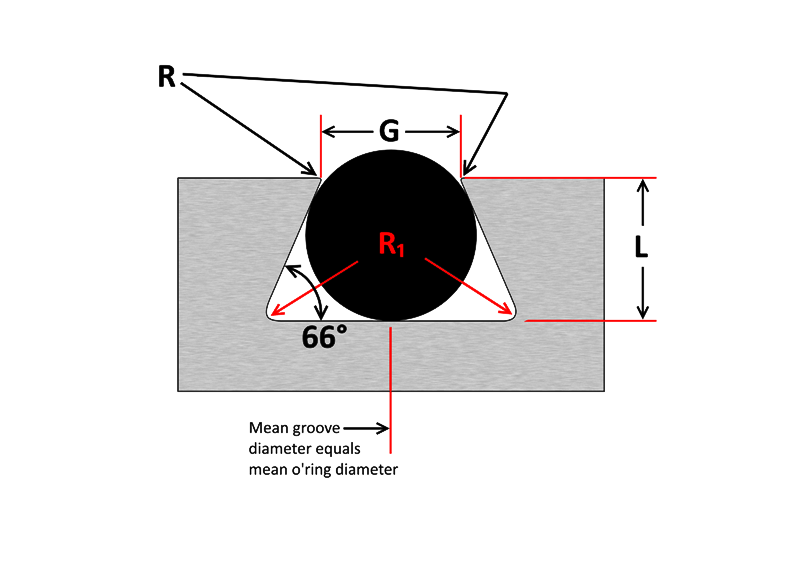

Triangular O Ring Grooves Mechanical Seal Engineering Eng Tips

Depending on your application you can have the groove be cut in either the piston or the boreA video to demonstrate the built in ORing generator using Autodesk Inventor 11 Not so much a tip or trick, but many Inventor users are unaware of the deORing Groove Design 1 The following sizes are not normally recommended for dynamic service, although special applications may permit their use 2 Clearances shown are based on 70 durometer materials The clearances must be held to an absolute minimum consistent with design requirements for temperature variations and should not exceed the

2

O Ring Groove Design Global O Ring And Seal

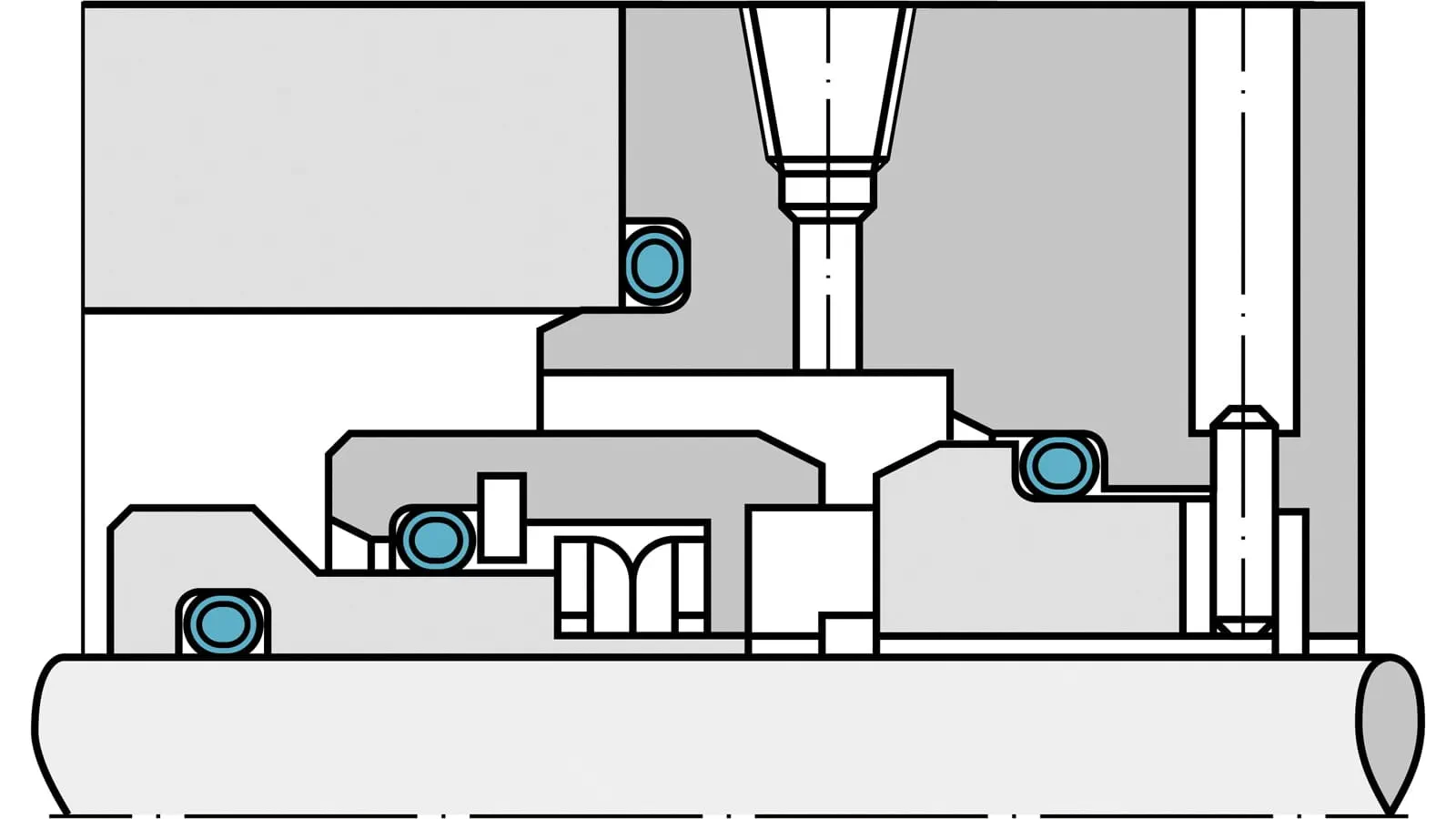

Oring groove design considerations and engineering guides for static face seals, metric orings, static dovetail orings, static rodpiston orings and dynamic rodpiston orings Find the right oring groove design and easily order your oring online from theThe ORing Store LLC ORing Groove Chart ORing Cord Stock OSK™ Assorted ORing Kits OSK™ ORing Repair Kits OSK™ Hydraulic Seal Kits OSK™ Air Nailer ORing Kits ORing Lube ORing Tools AS568 ORings (Inch) Metric ORings (mm) OSK Pool, Spa & Pump Orings Hydraulic Seals Inch ORing Glue & Thread Sealant Vulcanized ORings ORing Splice Kits & Tools Hydraulic SealsThe Oring is installed in a housing that is machined either as an outside groove or an inside groove in one of the two cylindrical parts The housing dimensions for static radial sealing Orings are listed in the size lists Housing groove edges

4 Common Mistakes In Designing For An O Ring Axial Face Seal Hot Topics

Fep O Rings Trelleborg Sealing Solutions

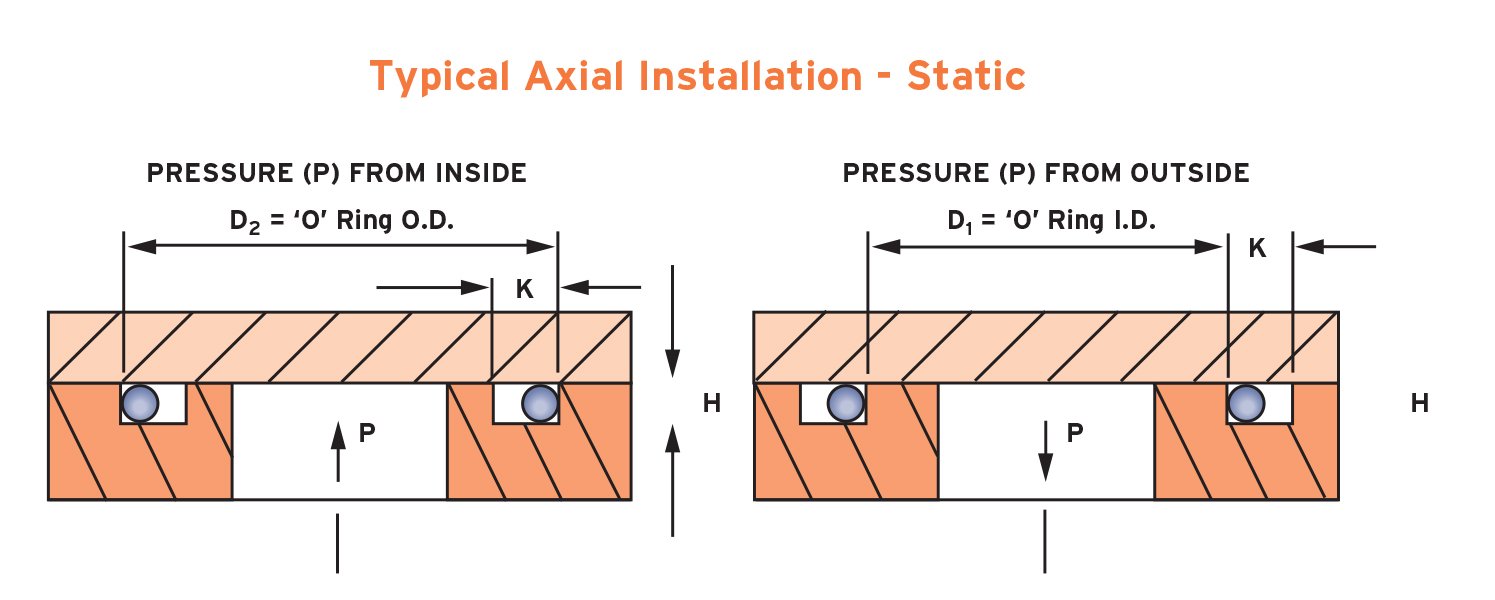

DESIGN DIMENSIONS FOR ORING INSTALLATION Orings are normally used as seals in several ways, and dimensions of the groove or gland will also vary with the cross section of the ring, the type of operation, and the amount of pressure used in the system These dimensions will also be different if the Oring is sealing a liquid which has a low volumeORing design for axial seals is similar to that for radial seals, with the important points summarized below The ORing must be compressed by a predetermined amount, and this compression determines the ORing crosssection diameterBe it dynamic or static operation, radial or axial loading, vacuum or high pressure

O Ring Installation Design And Specification Static Flange Application Engineers Edge

1

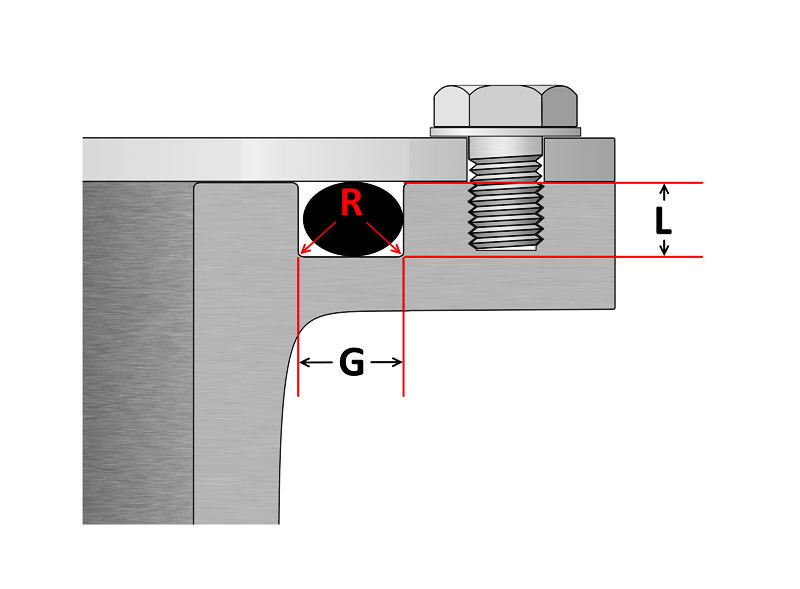

ORings West's goal is to be recognized globally for quality, reliability and expertise in all aspects of our business Our policy is to provide a management system and a working environment that emphasize predetermined quality objectives through continual enhancement of personnel capabilities and quality awarenessThe oring gland design is more complex for radial seals and requires both the piston and the bore to have precise geometry The bore and the piston have to be concentric to one another One of the faces will be completely smooth and one will have an oring groove cut into it;Oring seals are described in this section under "Scope of ORing Use" Orings are also used as lightduty, mechanical drive belts More information, including design criteria on Oring drive belts and their application will be found in ORing Applications, Section III 12 What is an ORing Seal?

Quad Ring Groove Design Daemar Inc

Llis

Technical Handbook Orings 2 Oring Sealing Principles The tendency of an Oring to return to its original shape when the cross section is deflected is the basic reason why Orings make excellent seals The squeeze or rate of compression is a major consideration in Oring seal design Elastomers may take up the stackup of tolerOrings are the epitome of elegant engineering The ring itself costs only a few cents, and the groove it goes in is simple and easy to manufacture But despThe Parker ORing Handbook has been a standard reference work used by seal designers for decades It contains comprehensive information about the properties of the most important sealing elas tomers, typical Oring application examples, examples of statically acting seal designs plus descriptions of conditions that may lead to Oring failure

Dovetail O Ring Groove Design Guide A Basic Recommendations

O Ring Groove Design Standard As568b Seal Design Inc

ORing Groove Design Guides Expert Application Engineering Assistance Oring groove design guides offer default dimensional guidance on the most basic oring groove design applications The best orings are useless without the right groove design which becomes increasingly important the more demanding the application environment3321 Oring seals and grooves When vacuum technology components are detachably joined, seals must be used to prevent ambient air from flowing into the vacuum To prevent this, there are, depending on the application and pressure range different types of seals Orings are the most frequently used of all sealsAn Oring seal is a means of preventi ng unwanted leakage or loss of fl uid or gas (i e media generally) The Oring is the most popular form of seal as it is simple to install and needs litt le installati on space Given correct grooving and material choice, the seal can

Standard Dovetail Grooves Dovetail Groove Engineering Design Guide

4 Common Mistakes In Designing For An O Ring Axial Face Seal Hot Topics

Suggested Groove Design for Quattro Seals™ Due to their unique fourlobed geometry, grooves for Quattro Seals are different than those for ORings In general, Quattro Seal grooves are deeper, as less squeeze is required to affect a positive seal Quattro Seal grooves are also narrower due to their ability to resist "spiral failureAS568B STANDARD ORING GROOVE DESIGN Contact Us For Assistance Or Samples Click Here and contact us today to receive a quote or if you have any questions regarding sizing × Dismiss alert The three main types of standard groove designs are Industrial Static also called Radial, Industrial Reciprocating also called Dynamic, and Face Seals alsoAn Oring seal is used to prevent the

Anyone Have Experience Designing An Asymmetrical O Ring Groove Under A Bolt Head Mechanical Engineering General Discussion Eng Tips

How To Use An O Ring In A Non Circular Groove Pattern

Groove width Design Guide 42 Guide for Design Table 42 410 Parker Hannifi n Corporation • ORing Division 2360 Palumbo Drive, Lexington, KY Phone (859) † Fax (859) wwwparkeroringscom Static ORing Sealing Static ORing Sealing †'O' ring cord 25 Commercial quality 'O' rings 25 'O' ring kits 26 Special packaging & kits 26 'O' ring lubricants 26 General design notes 2728 Housing design 2931 General information 31 Contact details 32 Quality production and inspection Our Materials Technology Centre houses one of Europe's most advanced facilities A noncircular face seal footprint might also be called a racetrack groove, a wandering groove or a custom plan view When using an Oring, the main design consideration is the corner or smallest radius (shown "r" in diagram) The inside radius should be at least three times the Oring cross sectional diameter

Static Axial Internal Pressure Gland Groove Design

Oring Ehandbook

Also, the groove width is generally less, as PTFE Orings are much less likely to roll in reciprocating applications than their elastomeric counterparts A surface finish or 16 rms or less is ideal, although rougher surfaces are acceptable if a shorter seal life can be tolerated A radius of 005" on the groove corners is advisableDovetail grooves are used to hold the Oring inplace on a face seal groove during during assembly and maintenance of equipment An undercut or dovetail groove has proven beneficial in many applications to keep the oring in place However, this is an expensive groove to machine, and thus should be used only when absolutely necessary Orings are the epitome of elegant engineering The ring itself costs only a few cents, and the groove it goes in is simple and easy to manufacture But despite this simplicity, the resulting seal is able to reliably hold many thousands of psi of pressure

Seals Eastern O Ring Rod Seal Design Guideline

Groove Design O Ring Seals Minnesota Rubber Plastics

O'ring Groove Design As important as the o'ring seal itself is the groove that the o'ring seats into The groove must be designed to accommodate not just the o'ring size, but also its intended usage;Technical Handbook Orings The sealing principle of the QuadRing®/XRing is nearly the same as the Oring sealing The initial sealing is achieved by the diametrical squeeze in ®a right angled groove The system pressure itself creates a positive sealing force Following are some advantages of QuadRings®/XRingsThis design is based upon the groove ID to limit side movement in the groove due to pressure direction (Fig 26) Due to the absence of any extrusion gap, these seal designs are capable of withstanding very high pressures on your orings without encountering extrusion problems

Metric O Ring Groove Design Reference Guide

O Ring Groove Design Global O Ring And Seal

If you are designing a face seal, select the ORing with an inside diameter which will position the ORing on the side of the groove opposite the pressure Click here for more information on face seal groove design Note the ORing inside diameter for the next step Calculate the Seal Stretch Using Equation 1, calculate the installed seal stretch

O Ring Cross Section O Ring Groove Design Data

O Ring Groove Design Standard As568b Seal Design Inc

O Ring Wikipedia

Oring Ehandbook

Design Of O Ring Seals Ppt Video Online Download

2

O Ring Groove Design Seal Design Inc

O Ring Groove Design Sealing Australia

What Is An O Ring Selection Material And Storage Barnwell

O Rings Allied Metrics Seals Fasteners Inc

O Rings An Overview Sciencedirect Topics

O Ring Groove Design Sealing Australia

O Ring Groove Design Guides Engineering Quick Reference

Groove Design Quad Ring Seals Minnesota Rubber Plastics

Designing Axial Static O Ring Grooves To Industry Standards Grabcad Tutorials

1

O Ring Groove Design Seal Design Inc

Buy O Rings Seals Custom Molded Rubber Engineered Plastic All Seals

O Ring Installation Design And Specification Static Cylindrical Installations Engineers Edge

Seal Design O Ring Design O Ring Design Guide

Seal Design O Ring Design O Ring Design Guide

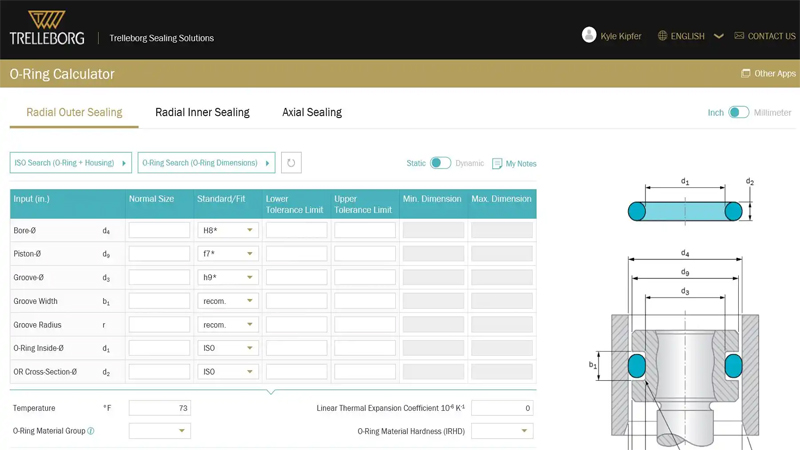

O Ring Calculator Trelleborg Sealing Solutions

1

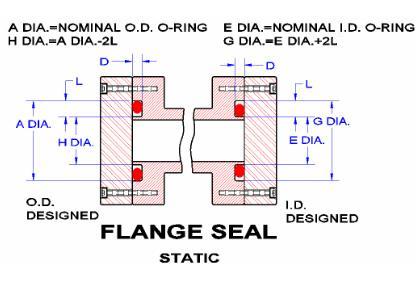

Seals Eastern Flange Seal O Ring Design Guideline

O Ring

Designing Axial Static O Ring Grooves To Industry Standards Grabcad Tutorials

Static O Ring Face Seal Groove Design Guide

O Ring Groove Design Guides Engineering Quick Reference

O Rings O Yeah How To Select Design And Install O Ring Seals Tarkka

2 Design And Detail Information O Rings Stock O Ring Webshop

How To Design An O Ring Groove Vizeng

O Ring Groove Dimensions Calculator Precision Polymer Engineering

O Ring Groove Design Guides Engineering Quick Reference

Untitled Document

O Ring Seals Roy Mech

What You Need To Know About Designing Axial Seals Hot Topics

O Ring Groove Design Metric Seal Design Inc

O Ring Groove Design Sealing Australia

Fact Book Design Guide 4 10

O Ring Groove Design

2

O Ring Groove Design Global O Ring And Seal

O Ring Groove Design Guides Engineering Quick Reference

How To Properly Choose Commercially Available O Ring Cross Sections Performance Seals Inc

O Rings For Oil Gas Applications Trelleborg

O Rings O Yeah How To Select Design And Install O Ring Seals Youtube

2

Buna O Ring O Ring In Houston And Minneapolis Dichtomatik

Sealcalc

O Rings O Yeah How To Select Design And Install O Ring Seals Tarkka

Ruander Com Quick O Ring Groove Design Guide

O Ring Groove Design Global O Ring And Seal

Gland Design Oringsusa

1

Dovetail Gland Design Dovetail O Ring Groove Dovetail Glands

How To Design An O Ring Groove Vizeng

Efunda Introduction To O Rings

Static O Ring Face Seal Groove Design Guide

Dynamic O Ring Design Chart Marco Rubber Plastics Custom O Rings Supplier

Sae J1453 O Ring Face Seal Groove Size Chart Knowledge Yuyao Jiayuan Hydraulic Fitting Factory

How To Use An O Ring In A Non Circular Groove Pattern

O Ring Groove Design Sealing Australia

O Ring Groove Design Rubber Shop

What Is An O Ring Selection Material And Storage Barnwell

Groove Design Quad Ring Seals Minnesota Rubber Plastics

Groove Design O Ring Seals Minnesota Rubber Plastics

Groove Design Gland Design O Ring Groove Gland Design

Design Of Oring Seals Design Of Oring Seals

Seals Eastern Plug Seal O Ring Design Guideline

Ficient Design Static O Ring Groove Design Mechanical Engineering

Oring Ehandbook

O Ring Seals Roy Mech

O Ring Groove Design Global O Ring And Seal

Static O Ring Design Chart Marco Rubber Plastics Custom O Rings Supplier

O Ring Groove Design O Ring Groove Dimensions Mykin Inc

O Ring Calculator Ceetak Sealing Solutions

O Ring Groove Dimensions Calculator Precision Polymer Engineering

How To Design An O Ring Groove Vizeng

0 件のコメント:

コメントを投稿